An extensive expertise for technical textile applications

The products we develop in this field aim to meet the specific technical constraints of our customers. It may be the search for particular textile performances, such as resistance (to heat, traction, cutting, abrasion, perforation), elasticity, conductivity, elongation. The goal may also be the development of yarns suitable to difficult weaving or knitting conditions, due to the use, for example, of fragile materials.

Specifically, we specialize in:

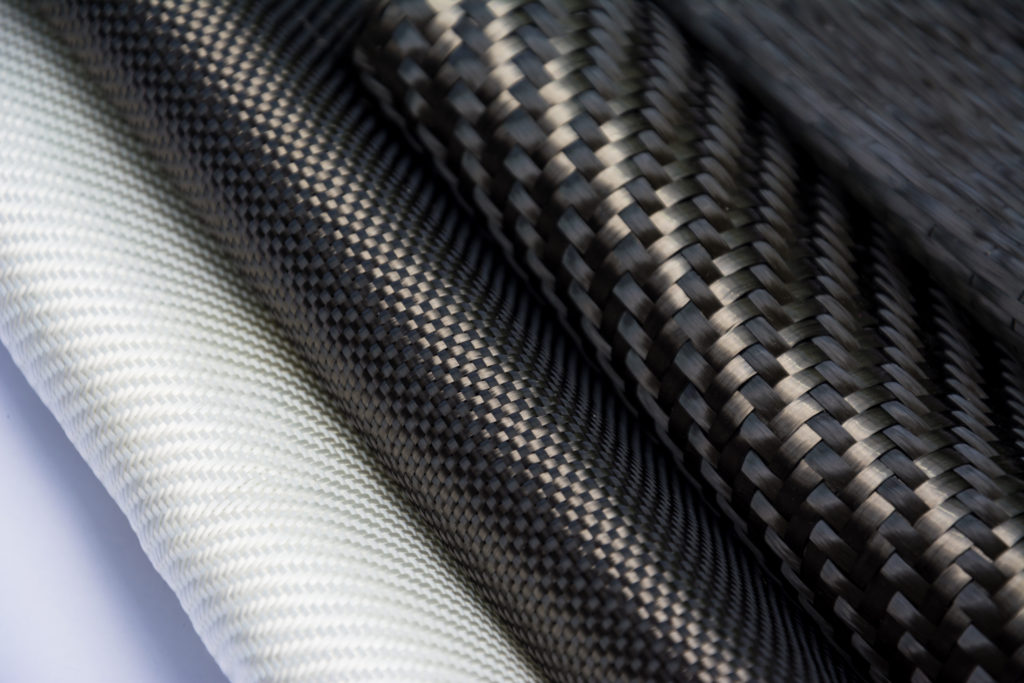

- Assemblies of materials such as HT polyester, polyethylene, polypropylene, aramid, stainless steel, metal, basalt, glass, PVA, carbon fiber. In any case, we are flexible on composition, final count, twist level, within the limits of the materials.

- Texturing of continuous filaments while preserving maximum tenacity.

We assist with following conditions:

- Contract manufacturing

- Production on specifications

- Audit of our procedures

The markets we mainly cater to are:

Individual protection

MOULINAGE DU PLOUY - EMILE TARDY is the first company in France in 1990 to have assembled carbon yarns with PES or PA bases.

Since then we have expanded our combinations of antistatic yarns to include, but not only, cotton and modacrylic.

We work with all the carbon fiber brands on the market such as : Belltron® Negastat®, Resistat®, No-Shock®.

We can accommodate any situation regardless of use such as:

- Protection against electric arcs;

- Clean rooms (to avoid the deposition of particles on electronic components);

- Filtration;

- Interior decorations which allow for dissipation of static electricity for greater comfort.

We offer a stock service for our standard references. Other combinations require a lead time of 2 to 4 weeks, longer for specific requests.

We also carry out special coverings for the most challenging working environments.

Filtration

Thanks to our expertise in texturing, we have developed special yarns for filtration. Crimp and elasticity are suitable for fabrics used in the extraction of materials such as iron ores.

Regarding air filtration, we offer carbon fiber based combinations designed to trap particles, whose presence can pose a risk to the safety of highly volatile industrial sites.

Composite

MOULINAGE DU PLOUY carries out assemblies made up, for example, of glass + PEEK or glass + PP, used in the making of reinforcements for hybrid composites

MOULINAGE DU PLOUY’s main assets are :

- Adaptation of standard machines to function with nonstandard textile materials;

- Assembly processing to accommodate customers' needs (texturing, twisting, covering, cabling, air texturized commingling);

- State-of-the-art laboratory to provide all technical sheets, inspection reports, and certificates.

Industries serviced but not limited to:

- Medical

- Industry

- Aerospace

- Nautic manufacturing